Case Studies

Discover our customers success stories around the world

Energy and cost savings by retrofitting a state-of-the-art dry grinding separator system in a cement plant

Sebald Zement GmbH, a family-owned company in Frankenalb, Germany, was founded in 1860 to produce quicklime from local limestone. It switched to cement production before the 20th century, earning a strong reputation for quality. In 1969, the plant was upgraded with a new mill to improve production and quality, and in 1975, a first-generation dynamic separator was installed. Nearly 50 years later, the company upgraded to a modern separator to boost production, reduce energy consumption, and expand its product range. Cemtec was awarded a contract to replace the dynamic separator in a cement grinding plant in Germany with a third-generation separator (Cemtec CTC-0075)

Challenge

- Poor separation efficiency with 1st generation classifiers

- Production of higher cement qualities, with the existing separator due to restrictions in cut size

- Short time frame for engineering tasks

- Limited space at construction site due to the historically grown plant structure

- Heavy dust emissions by reject belt conveyor

Solution

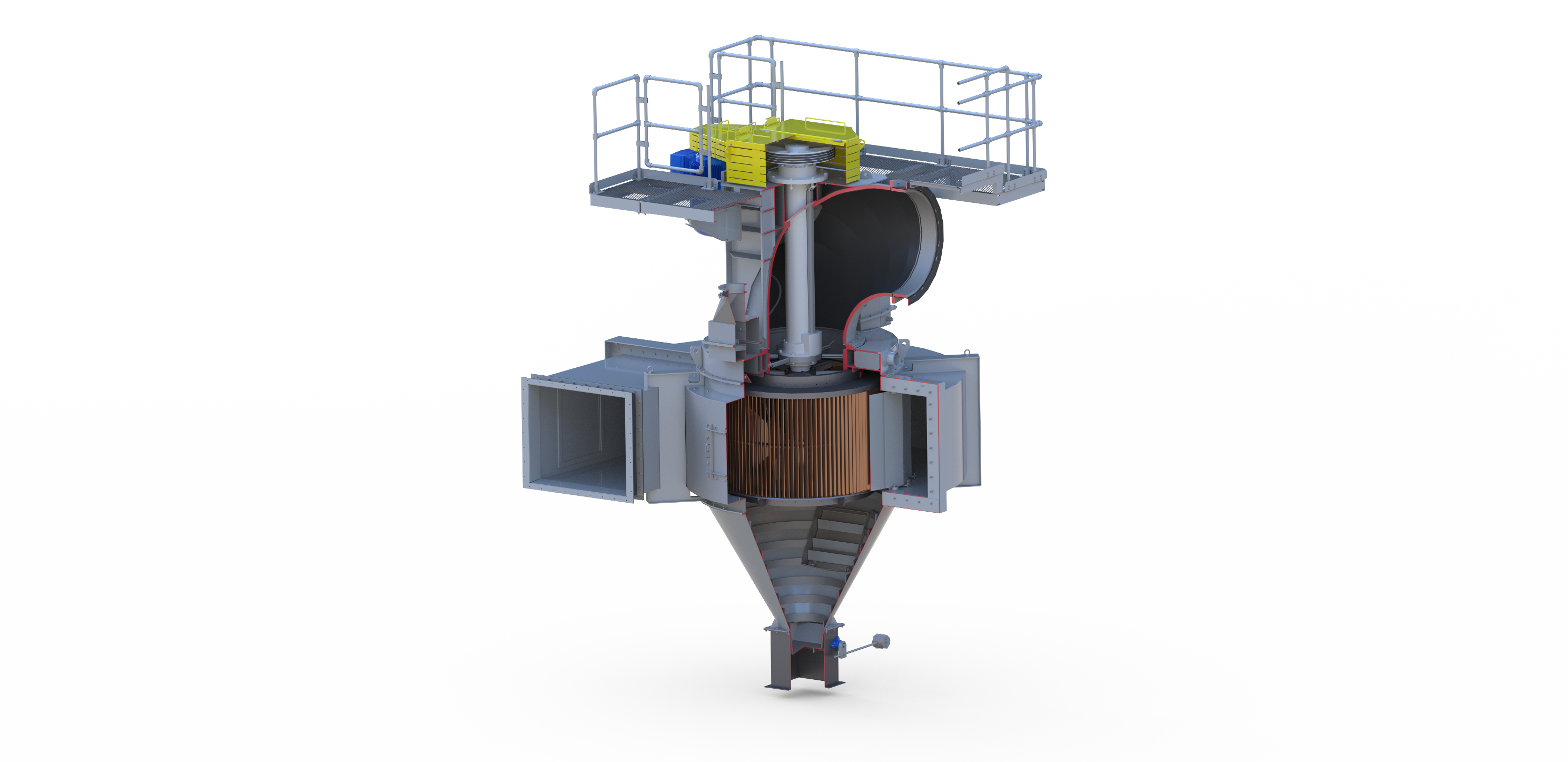

- Replace the existing separator with a 75000 m³/h Cemtec CTC-0075

- It was used in a closed air circuit with two dedusting cyclones to remove the main part of the finished product from the separator air stream

- Replace the reject belt conveyor from the separator to the mill inlet with an air slide

Result

- The steepness of particle size distribution increased significantly

- Throughput increased by approx. 5% for one cement type and 12.5% for the other after the separator was replaced

- Specific energy consumption decreased by 5.5% and 14%

- The Cemtec CTC series can achieve cut sizes down to 16 µm (98% passing) for producing high-quality cement

CEOPS Analyzer

The CEOPS is a customized solution, which provides online measurement of the particle size distributions. It is entirely developed and manufactured by CEMTEC in Europe. This tailored approach guarantees representative sampling required for proper regulation of the plant. There are multiple communication interfaces to integrate the CEOPS unit into higher-level control systems, offering various options for improved control of grinding circuits. For the measurement, a Malvern Insitec laser unit is incorporated into the CEOPS system.

The CEOPS was connected with a multi-pattern controller to optimize the grinding parameters of the cement mills. In this application, the basic operational principle can be described as follows: The controller gathers information from the plants’ main PLC (grinding chamber filling degree, operational set points) and the CEOPS (fineness of the product), generating optimized set points for the fresh feed and the dynamic separator based on this data.

Specific challenges and proposed solution

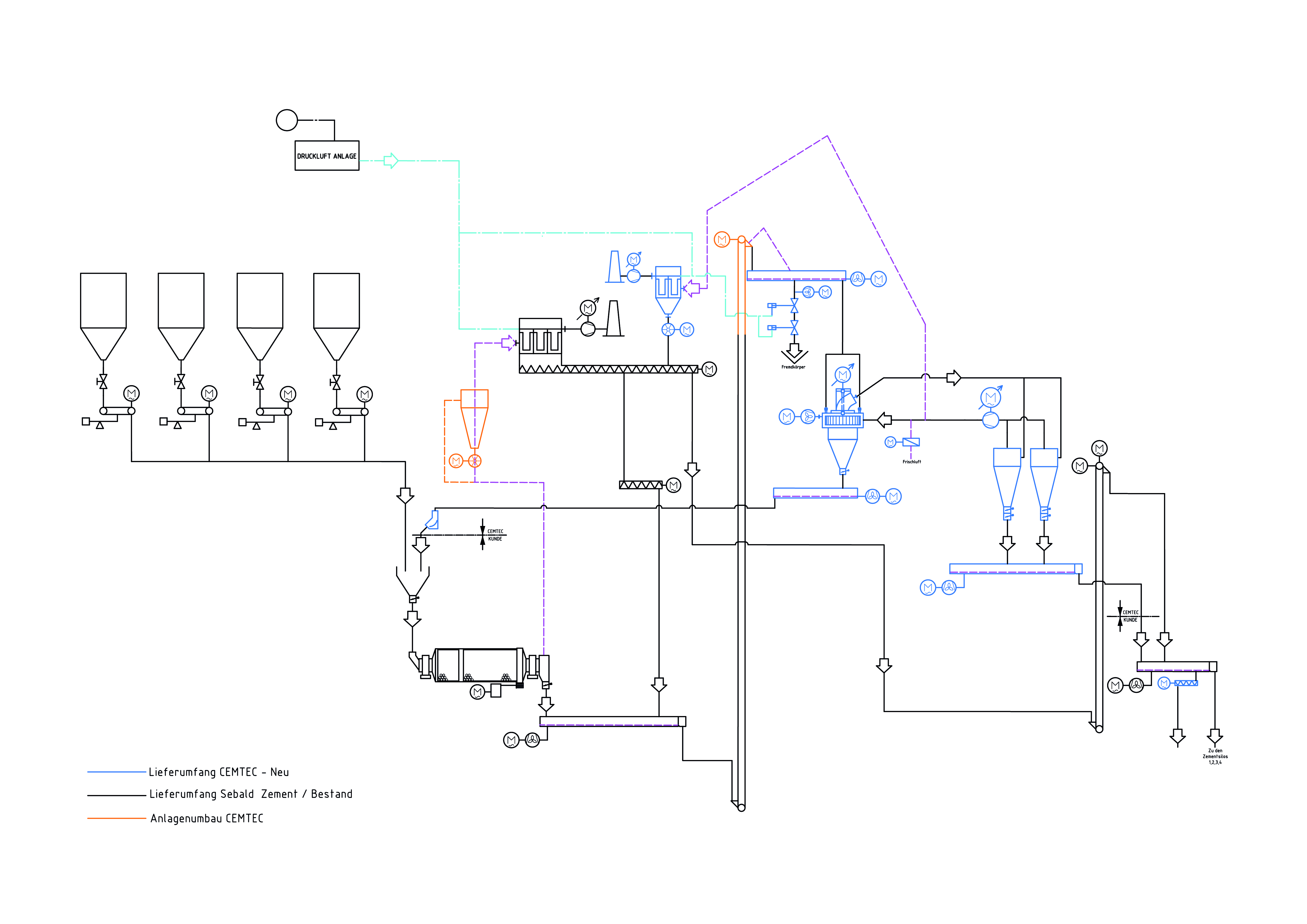

The existing cement mill (ø 2.8 x 13.75 m, 1500 kW) was originally equipped with a first-generation Polysius separator in 1975. Based on data from Sebald Zement, it was decided to replace the separator with a 75,000 m³/h Cemtec CTC-0075. The new separator operates in a closed air circuit with two dedusting cyclones and a bag house filter to remove the finest particles. The finished cement is transported to storage via existing equipment. The complete cement grinding line flowsheet, with new and modified equipment in blue and orange, is shown in Figure 2.

Sebald plant/separator building before retrofit

Detail engineering began in May 2019, preparing for the planned 2020 shutdown. The customer decided to replace the reject belt conveyor with an air slide to reduce dust emissions. To accommodate the air slide, the new separator and roof were raised, requiring the lengthening of the 45-year-old bucket elevator to reach the separator's feed height. Additionally, the cyclone in the mill dedusting system was removed to make space for a new filter. A slide scale was also installed at the reject air slide discharge to accurately monitor the circulating load.

The project faced challenges including a tight engineering timeline, limited space due to the plant's historical structure, proximity to train tracks, and a restricted execution window. Despite these difficulties and incomplete documentation of old equipment, Cemtec completed engineering on time in September 2019. All equipment was sourced from reputable European suppliers, meeting the customer’s specifications and quality requirements.

Sampling and initial process conditions

In November 2019, Cemtec conducted a detailed joint investigation to gather a comprehensive comparison. This involved sampling various materials from the grinding plant, including mill outlet, separator fines, separator coarse, filter dust, and finished products for two different cement qualities. They also sampled raw materials like clinker, limestone, and gypsum to get a complete understanding of the grinding line's performance while recording operating parameters and measurement values.

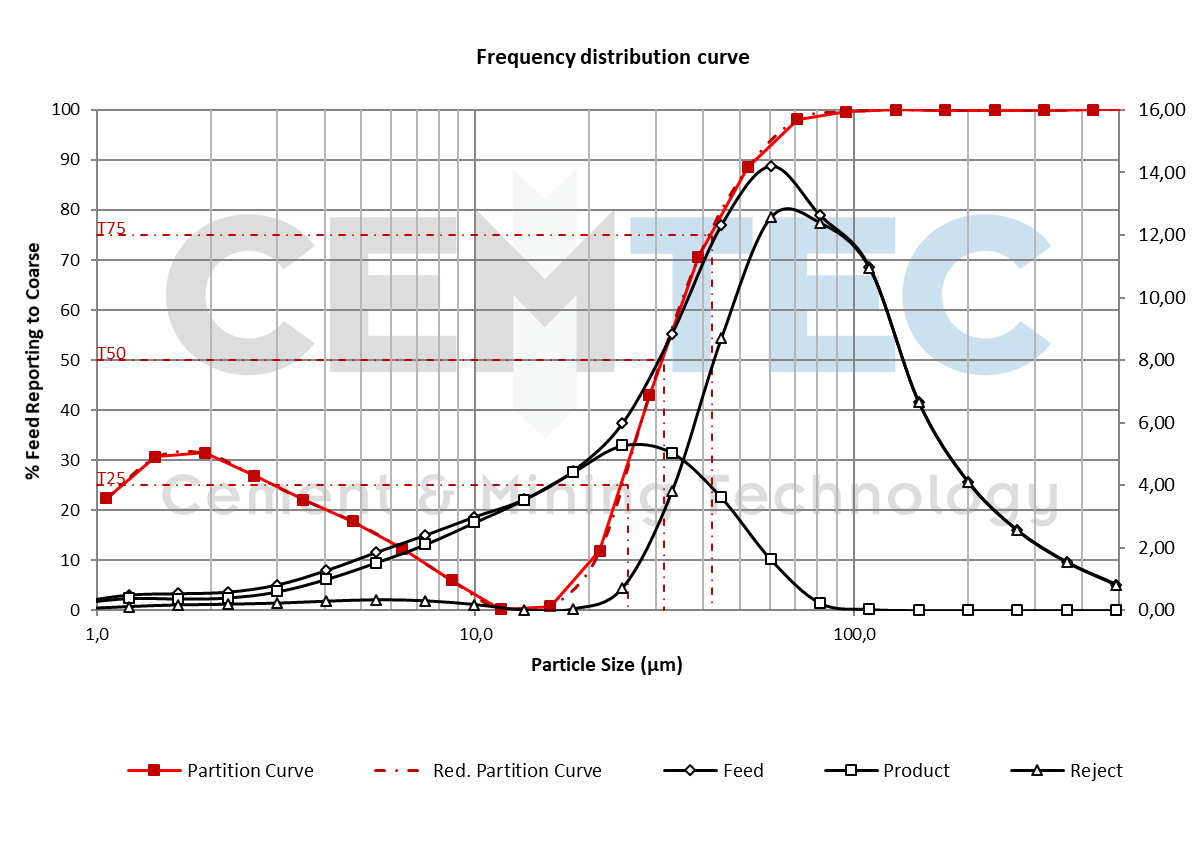

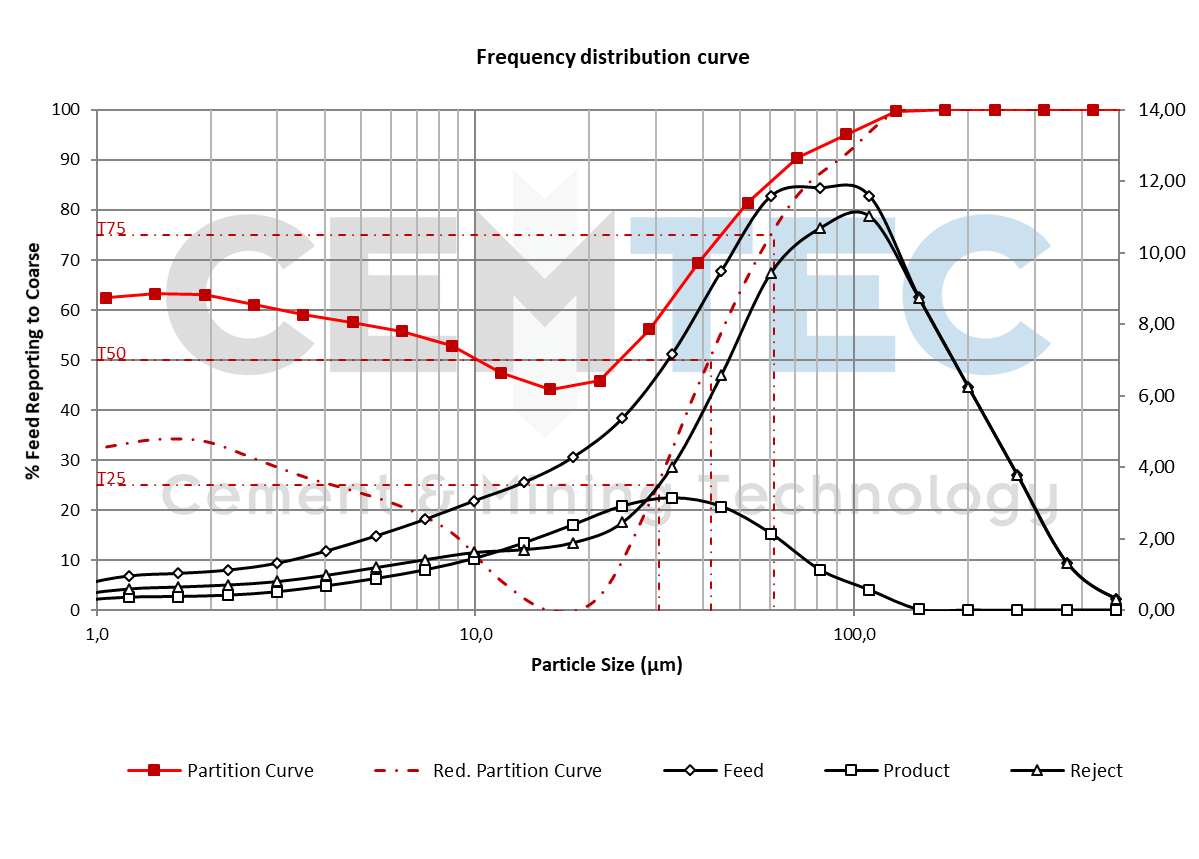

Cemtec's in-house laboratory analyzed the samples and provided a detailed report to the customer. The samples were tested for particle size distributions, and the finished cement's specific surface area was measured using the Blaine method. The results indicated high by-pass ratios for both cement qualities, suggesting significant optimization potential. Figure 4 shows the resulting partition curve for one cement quality. test results were also used to confirm process guarantee values, which helped compare the grinding plant's performance before and after the separator replacement.

Realisation and work progress

Detail engineering began in May 2019, preparing for the planned 2020 shutdown. The customer decided to replace the reject belt conveyor with an air slide to reduce dust emissions. To accommodate the air slide, the new separator and roof were raised, requiring the lengthening of the 45-year-old bucket elevator to reach the separator's feed height. Additionally, the cyclone in the mill dedusting system was removed to make space for a new filter. A slide scale was also installed at the reject air slide discharge to accurately monitor the circulating load.

The project faced challenges including a tight engineering timeline, limited space due to the plant's historical structure, proximity to train tracks, and a restricted execution window. Despite these difficulties and incomplete documentation of old equipment, Cemtec completed engineering on time in September 2019. All equipment was sourced from reputable European suppliers, meeting the customer’s specifications and quality requirements.

Result and Summary

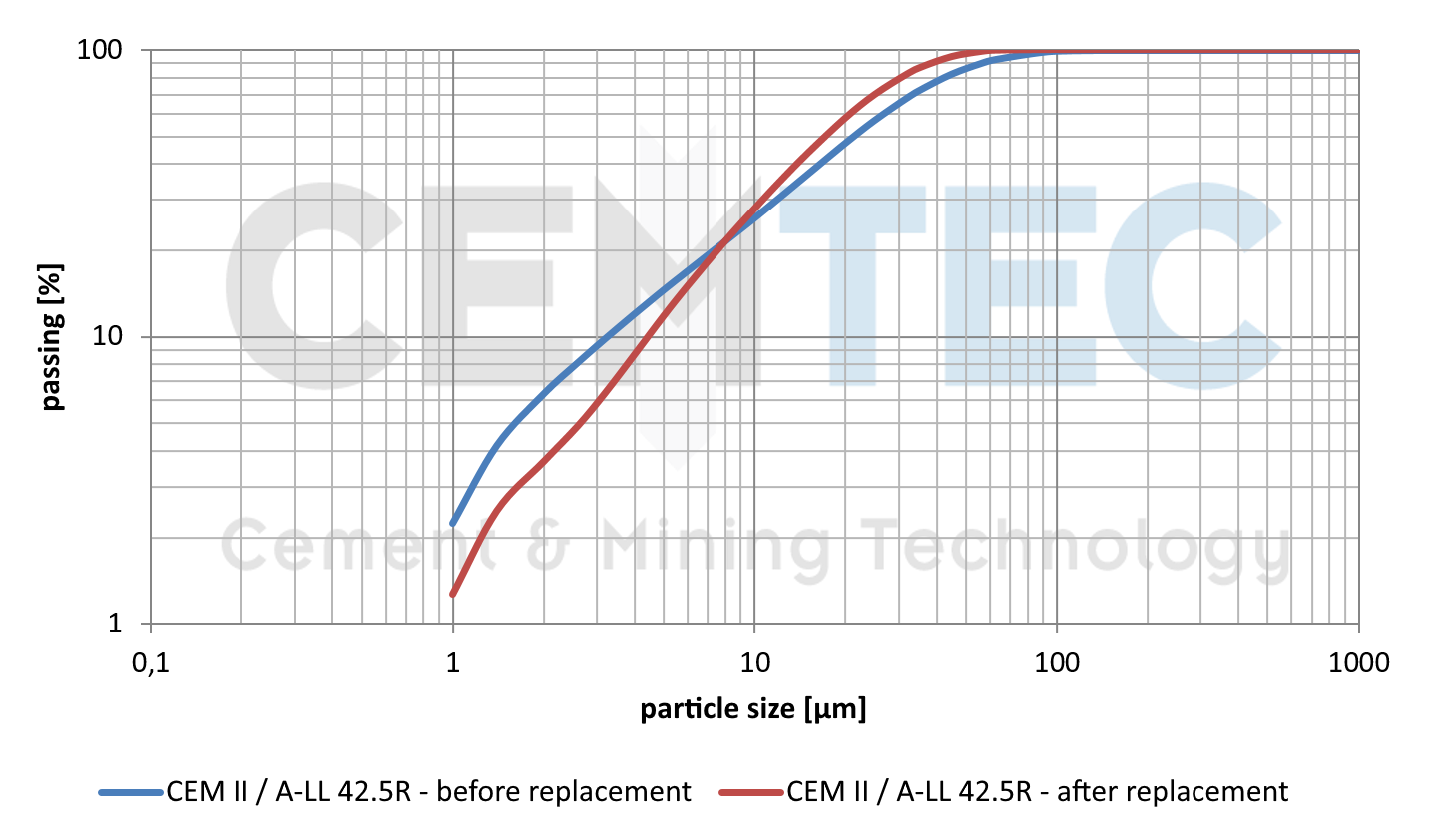

In May 2020, after some time to optimize and gain experience with the new plant, another sampling campaign showed that all guarantee values had been met. Figure 7 shows a comparison between the finished cement product before and after the replacement of the separator. As the diagram shows, the steepness of particle size distribution increased significantly.

In Figure 8, the partition curve for one cement type can be seen. The reduction of the global bypass is visible and nearly zero. The replacement of the separator increased throughput by approximately 5% for one cement type and 12.5% for the second type, specific energy consumption accordingly decreased by 5.5% and 14%. All this was achieved at slightly higher Blaine values, so the effect would even be greater at the comparable Blaine values.

| Cement type | Throughput [%] | Specific grinding energy [%] |

|---|---|---|

| CEM || A-LL 32.5R | 5 | -5.5 |

| CEM || A-LL 42.5R | 12.5 | -14.0 |