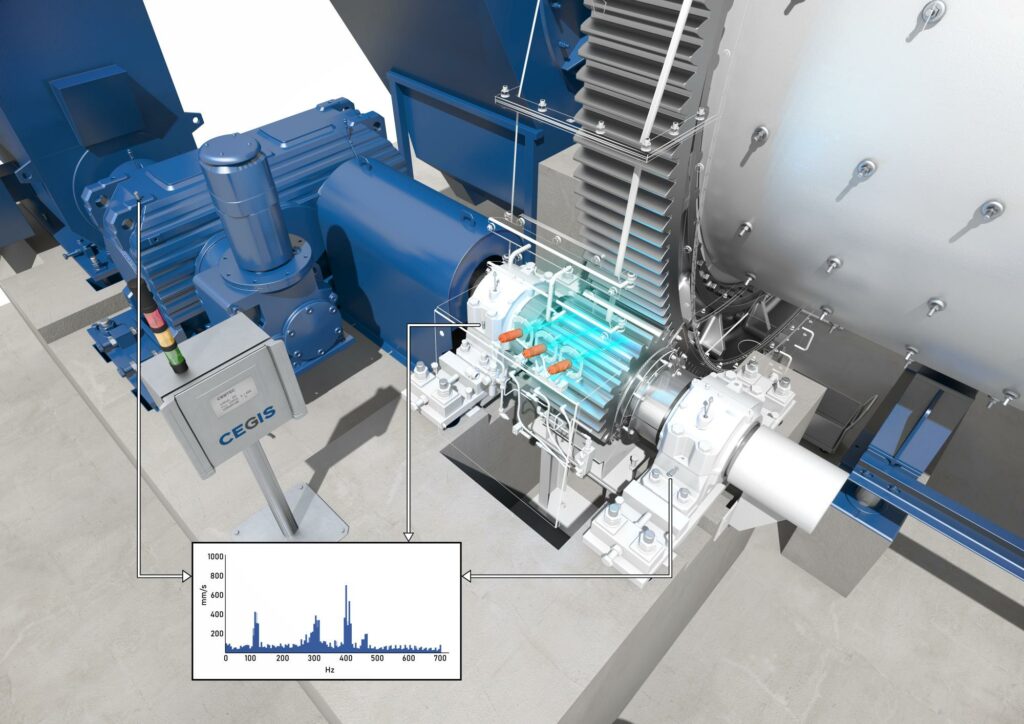

The CEGIS system allows real-time data collection and offers insights into the health of your machinery. It alerts you of any potential issues, allowing for timely maintenance or adjustments, ultimately preventing costly downtime. The system also provides detailed performance reports, allowing you to optimize the performance and life expectancy of your equipment.

Gear Inspections

Real Time Monitoring of Mill Mechanics

Monitoring the machine’s condition is an absolute prerequisite for condition-based maintenance (predictive maintenance). This opens up new possibilities for planning spare and wear parts as well as machine operators and service personnel in a targeted manner. Plant efficiency can be increased compared to reactive and preventive maintenance.

As a manufacturing company, you demand the highest possible system availability to generate maximum yields.

To do this, you need a system that monitors the condition of your mill drive and provides suggestions for maintenance at the right time. Not when it‘s too late.

With CEGIS you can optimize your system in a targeted manner

- Foresee imminent damage, thereby increasing plant availability and minimizing repair calls

- Minimize your spare parts costs. Replace only those parts where it is necessary

- All components are in use until they are worn out, but never beyond that

- You will be informed in good time about the need for an exchange.

Application

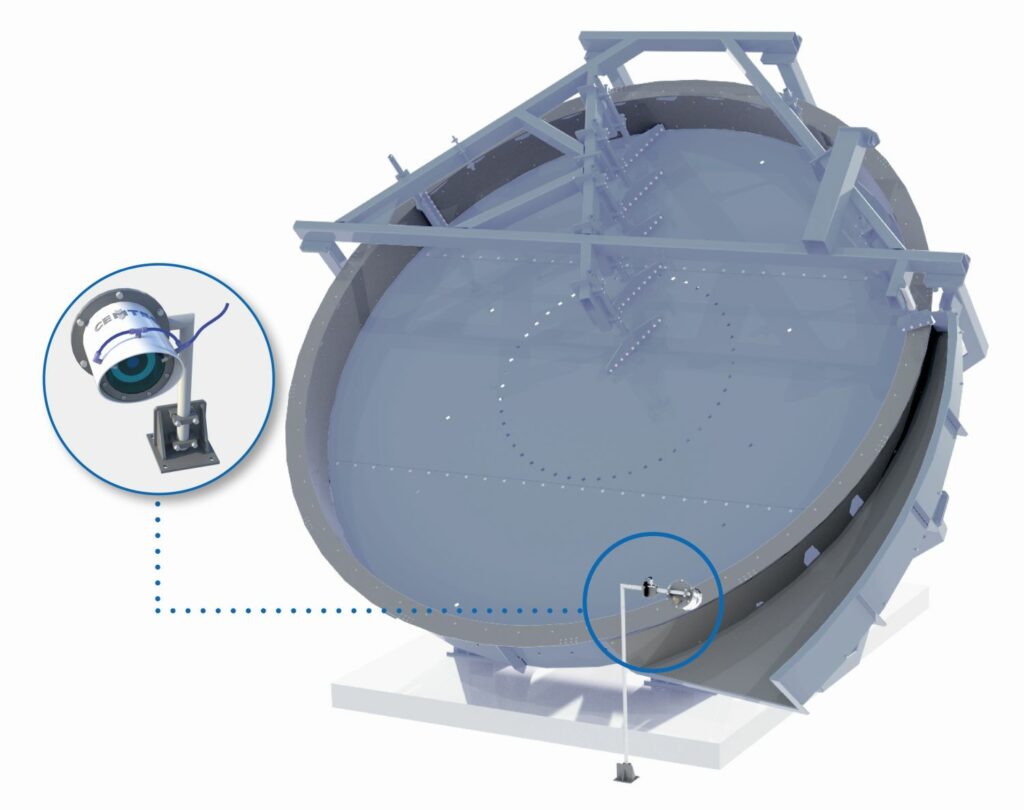

The CEGIS system is a universal tool for monitoring your mill mechanics. The focus is on monitoring the pinion temperatures and vibrations caused by the pinion bearings. This can optionally be flexibly expanded by additional monitoring of the main mill bearings and motor or gear vibrations.

For the evaluation, the values are referenced during commissioning and their long-term development is observed and evaluated.