Smart thinking, Smart grinding

A stricter regulatory environment is posing challenges for the mineral raw material processing industry. It is becoming difficult for companies to find skilled labor to oversee complex production processes with the ability to handle a constant deluge of operational data.

This reality often forces them to adopt higher operational safety margins, a decision with double-edged impact. While it ensures the continuity of plant operations, it can lead to significant fluctuations in product quality and a marked reduction in plant performance.

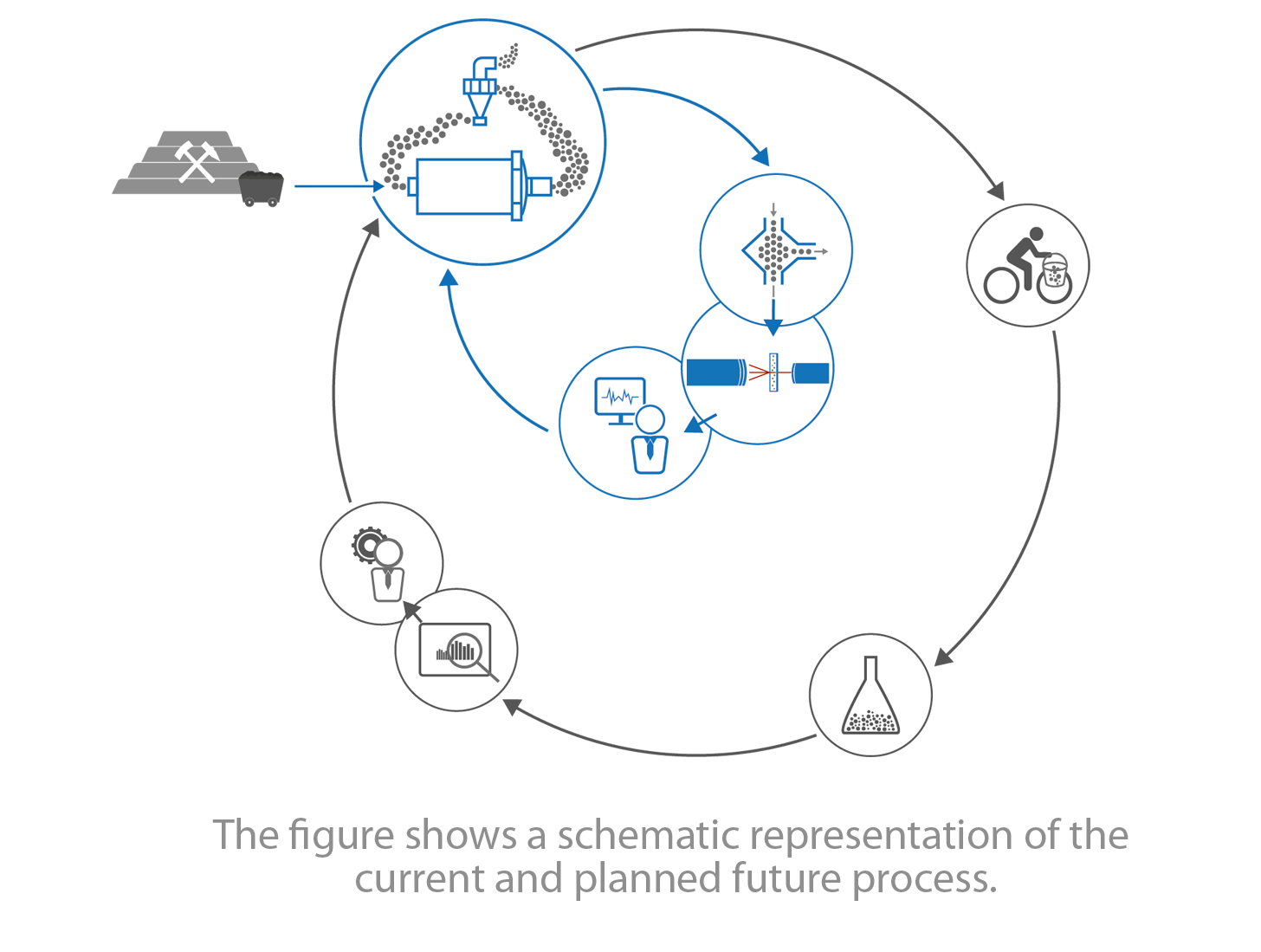

An ever-increasing global focus on environmental sustainability makes it increasingly important for plants to be more energy efficient. In this challenging landscape, smart grinding has the potential to transform traditional methods through the application of data science and machine learning for controlling dry grinding and sifting circuits.