Mixers

The perfect system for your requirements

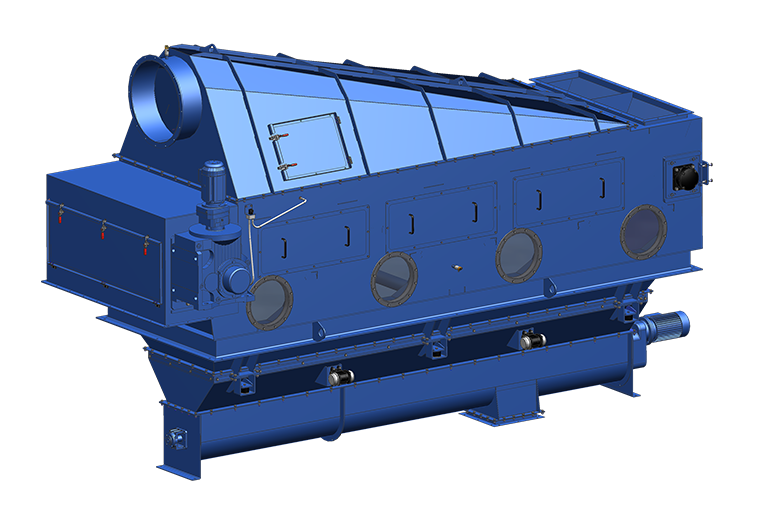

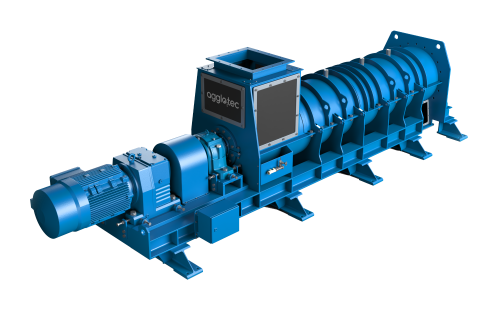

Mixers are mainly used for raw material mixing and pre-humidification / pre-granulation upstream of the pelletizing disc. The retention time necessary to achieve the required mixing quality depends on the properties of the raw materials and can be determined in our pilot plant. The various sizes and designs are also adapted to industrial mineral applications.

Unlike standard plough shear mixers, the high-intensity model is characterized by a high specific power (kW/m³). Pelletizing of fine powders requires intensive agitation of solid matter, binding agent, and water. Due to high turbulences inside the mixer, an optimized feeding material to the downstream pelletizing disc is guaranteed.

Tailored solutions for every requirement

When configuring the mixer size according to product specifications, tests can be carried out in our in-house laboratory to ensure the correct process design and machine sizing.

The mixers are available in various designs and sizes

| Type code | Ø [mm] | Length [mm] |

|---|---|---|

| PMX-30x115 | 300 | 1.150 |

| PMX-40x150 | 400 | 1.500 |

| PMX-60x225 | 600 | 2.250 |

| PMX-80x300 | 800 | 3.000 |

| PMX-100x300 | 1.000 | 3.000 |

| PMX-100x375 | 1.000 | 3.750 |